more than 50 years

We’ve been doing this for more than 50 years and have over 14,000 machines installed globally. And what all those customers will tell you is that if you choose Milltronics you will get a better built machine with more standard features for a great price.

Milltronics USA is located in Indianapolis, Indiana and is a member of the Hurco Companies Machine Tool Group.

complete cnc solution

Milltronics offers 50 different models of CNC milling and CNC turning machines for toolroom and production environments. The lineup includes toolroom mills and toolroom lathes, general-purpose and high-performance vertical machining centers, CNC lathes, and bridge mills. Their versatile product line offers something for everyone.

Beyond Expectations

See the machines in action and experience firsthand how Milltronics can transform your shop. New Machines. New Technology. Beyond Expectations.

ABOUT milltronics

For over 50 years, Milltronics has been committed to seamlessly surround machine shop owners and manufacturers with fast and reliable full life-cycle support to make great products. We proudly serve the CNC machining industry worldwide by offering our innovative control and manufacture a complete line of vertical machining centers & lathes for toolroom and production environments. Each machine is configured to our customers’ specifications and business needs while providing the most affordable solution to match the investment and accelerate the ROI.

We have built our reputation on three differentiators:

• Intuitive & Innovative Control

• Accurate & Reliable Machines

• Dedicated & Solution-Minded People

Since 1973 and with over 14,000 machine installations, these differentiators have allowed Milltronics to go above and beyond to provide our customers with exceptional machining performance, at a price they can afford, with the assurance that we will stand behind our products and be true to our word

“Adding equipment that we can rely on, count on, trust in, is something that is so important in our industry,” said Max Ashenbrener, sales manager of Manitowac tool & mfg.

“Bulletproof” and “maintenance free” is how the Manitowoc team described Milltronics machines. That kind of durability allows them to spend less time troubleshooting and more time manufacturing. Manitowoc has invested in 13 Milltronics machines thus far.

milltronics Product Categories

3-Axis Tool Room Mills

Milltronics has a long history of building tool room machines that can be run as manual, teach or full CNC with thousands of satisfied users. Popular in tool rooms, job shops, and tool & die, these machines are very flexible and can be used for a wide variety of different parts.

They offer two types of quill machines in a traditional knee style (VK) as well as a bed type (TRQ). The rigid head (TRM) machines are available in four different sizes starting with a compact 30 x 16 in model up to a large travel 78 x 33 in.

The TRM3016 is a tool room mill that offers large travels, speed, and power at a great price. The TRM3016 (pictured above) has “drop down” door openings for long part pass-through to help accommodate oversize parts.

General Purpose 3-Axis Vertical Machining Centers

VM Series:

The Milltronics VM Series are general-purpose, three-axis vertical machining centers designed to offer a strong blend of performance, reliability, and value. These belt-driven machines come standard with higher-end features—such as full enclosures, swing-arm tool changers, 10,000 RPM BIG‑PLUS® dual-contact spindles, and the intuitive 9000 Series (9000‑DGI) control—that other OEMs may charge extra for

The 9000 control enhances usability with graphical interfaces, conversational programming, and robust storage/performance capabilities

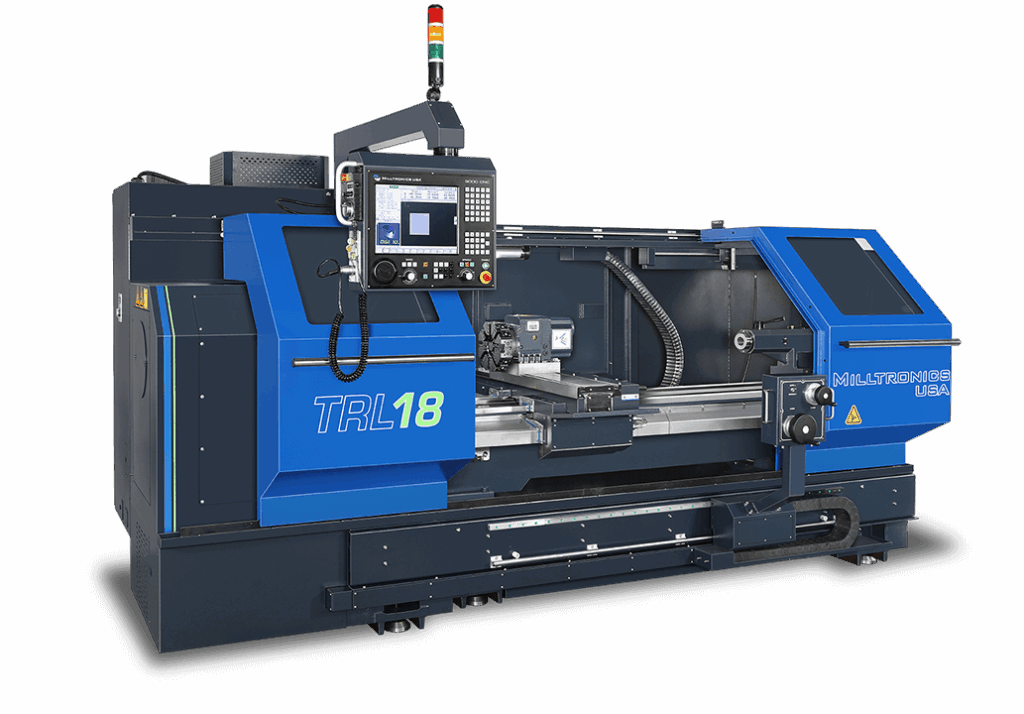

Tool Room Lathes

The TRL Series is Milltronics’ newest line of tool room lathes. They can be run manually or through the 9000 DGI control, which simplifies operation, shortens setup times, and provides features that reduce cycle times. TRL Series lathes provide a combination of robust turning and milling capabilities, designed for high-performance machining in a compact form.

These turning centers feature a gap bed, a swing that ranges from 16.7 to 27 inches, and a Z-axis travel that ranges from 66.5 to 84.6 inches. Chuck size is chosen during the purchasing process. TRL lathes sport fully balanced, direct-drive spindles for quiet, smooth turning, and heavy exterior ribbing on the headstock for added rigidity. An 8-position, bi-directional, automatic turret provides quick and reliable tool changes.

The bed, cross slide, and saddle are composed of Meehanite cast iron, which includes very high dampening characteristics. Heavily ribbed castings provide superior dampening, decreasing vibration and harmonics, providing aggressive turning ability. Each axis is driven using a high-precision, fully-ground ball screw. Each ball screw is supported on each end using angular contact thrust bearings to achieve high rapid traverse rates and thrust. The design of the tailstock allows for full cutting along the Z axis travel, and the oversized tailstock is ideal for supporting heavy work pieces.

What our customers say

"With rigid machines built for the long haul, a user-friendly control that shortens the learning curve and increases efficiency, and a responsive support and service team they can count on, we have found success with Milltronics. The machines are running great, and they’re easy to program. (We) collaborate with all our employees, and they also agree that they’re a nice machine to program and set up and run."

Brian Schmoll, Innovative Machine Specialists

hear directly from Milltronics Customer - midstate technical college

Interested in milltronics Products?

Contact us and we will provide a detailed quote of the products you’re interested in.

About Us

U-Tech is your local multi-line CNC distributor, bringing a strong and committed team with decades of experience in the machine tool industry.

We pledge to apply a total solutions approach to support our customers’ needs.

Contact info

Address (Florida):

21125 Cortez Blvd.

Brooksville, FL 34601

Phone: +1 352-443-5779

Email: info@utechcnc.com

Address (Southeast):

10234 Rougemont Lane

Charlotte, NC 28277

Phone: +1 980-500-8263

Email: info@utechcnc.com

© Copyright Utech CNC | All rights reserved